Fiber Spunlancing

Hydroentanglement, sometimes known as spunlacing, is a bonding process used in the manufacture of nonwoven materials, in which high-pressure technology is required.

Hydroentanglement systems utilize rows of highly pressurized water jets to impinge on the fiber web and twist fibers around each other.

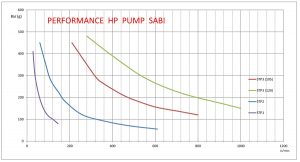

Sabi manufactures reciprocating plunger pumps to provide the high pressure water. Sabi produce reciprocating plunger pumps since 2001, with a wide experience in very demanding installations such as offshore and petrochemical application.

Sabi pumps’ operating points such as flow rate and pressure can be easily regulated during use, because all pumps are equipped with an electric motor suitable for frequency converter.

Hydraulic heads are made up of highest quality materials, typically stainless steel material for wetted parts and plungers with tungsten carbide surface coating.

Sabi can supply all accessories required for the specific application including pulsation dampening devices (eg. resonator), therefore supplying a “turnkey” pumping unit system.